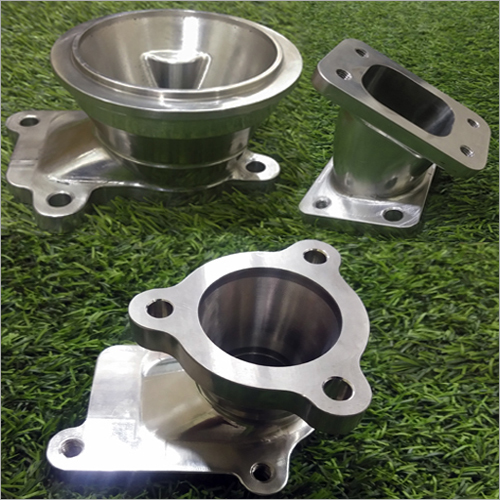

Industrial CNC Machined Components

Product Details:

- Load Capacity Up to 1000 kg (design specific)

- Accuracy Up to 0.005 mm

- Thread Type Metric/UNF/UNC threads

- Coating Optional anodized/coated/painted surface

- Cutting Speed 50-500 mm/min

- Weight 50 grams to 2 kilograms (component dependent)

- Shape Custom geometric profiles

- Click to View more

X

Industrial CNC Machined Components Product Specifications

- Up to 1000 kg (design specific)

- Up to 0.005 mm

- 0.01 mm

- Subtractive manufacturing, CNC milling, CNC turning

- Used in high-performance and critical-load environments

- Automotive, Aerospace, Manufacturing Equipment

- Finished, Smooth

- Industrial machinery assembly

- Optional anodized/coated/painted surface

- Metric/UNF/UNC threads

- Stainless Steel, Aluminium Alloy

- Yes

- 50 grams to 2 kilograms (component dependent)

- 50-500 mm/min

- Custom geometric profiles

- Machined Components

- 35-55 HRC

- 3-axis & 5-axis CNC machining center

- Diameter range 5mm to 100mm

- 1000-12000 RPM

Industrial CNC Machined Components Trade Information

- All India

Product Description

Industrial CNC Machined Components that we have are designed to be utilized in a lot of industrial machinery, equipment and plants. At our developed casting facilities, the components are precisely designed and fabricated by talented personnel using top-of-the-line metal and CNC machine of advanced technology as per industry standards. Over and above, Industrial CNC Machined Components are absolutely durable, corrosion proof, and are available in varied sizes, finishes, and grades at feasible prices to the respected patrons.

Precision and Quality Assurance

Our components are engineered to exacting standards with finish quality Ra 0.8-1.6 m, strict 0.01 mm tolerance, edge deburring, and chamfering. Comprehensive inspection using CMM equipment ensures each piece meets your precise specifications. RoHS and ISO 9001:2015 certifications guarantee reliability and traceability for all industrial uses.

Customization & Versatile Material Options

From stainless steel to aluminium alloys, choose material, coating, heat treatment, and design tailored to your needs. Send us your drawings in DXF, DWG, STEP, or IGES formats, and our team will deliver components with the exact tolerances and features required for your application, including threaded inserts and pre-drilled holes.

Protective Packaging and Export Support

Every item is packaged using protective foam and custom cardboard boxes, safeguarding them during transit to local or global destinations. As exporters, we efficiently manage both small (10 pcs) and bulk (up to 10,000 pcs) orders with lead times between 7 and 21 days, catering to manufacturers, suppliers, and wholesale needs across industries.

FAQ's of Industrial CNC Machined Components:

Q: How is the finish quality and accuracy of your CNC machined components ensured?

A: Our components feature a surface finish of Ra 0.8-1.6 m and accuracy up to 0.005 mm, achieved through advanced 3-axis and 5-axis CNC machining. Each part undergoes 100% dimensional inspection with a Coordinate Measuring Machine (CMM) to verify strict 0.01 mm tolerances before shipping.Q: What customization options are available for design, material, and finishing?

A: We offer customization in geometric profiles, dimensions, tolerance classes, material selection (stainless steel, aluminium alloys), surface coatings (anodizing, painting, or other finishes), and optional case hardening or quenching. Submit your design files (DXF, DWG, STEP, IGES), and we will manufacture components to your specific requirements, including metric/UNF/UNC threads, pre-drilled holes, and threaded inserts.Q: Can you handle both small prototype and large bulk production orders?

A: Yes, we cater to diverse production needs-from prototypes (10 pcs) to full-scale runs (up to 10,000 pcs). Advanced CNC equipment and flexible processes enable us to meet varying order volumes with consistent quality and efficient lead times (7-21 days depending on size).Q: What industries commonly use your CNC machined components, and what are their typical applications?

A: Our components are designed for high-performance and critical-load environments, making them ideal for use in industrial machinery, automotive assemblies, aerospace systems, and manufacturing equipment where precision, strength, and durability are vital.Q: How are your components protected and packaged for shipping?

A: Each machined component is encased in protective foam and housed within a custom cardboard box to safeguard against damage during transit. This meticulous packaging ensures products arrive in pristine condition for all clients, including exporters, suppliers, and service providers.Q: What compliance and certification standards do your products meet?

A: All components are RoHS compliant and manufactured under ISO 9001:2015 certified processes, assuring customers of environmental responsibility and consistent product quality suitable for international markets.Q: Are your components suitable for demanding operational environments, such as outdoors or marine settings?

A: Yes, our CNC machined components are engineered for high corrosion resistance, can withstand temperatures up to 200C, and are available with optional protective coatings, making them ideal for outdoor and marine applications as well as industrial settings demanding superior durability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free