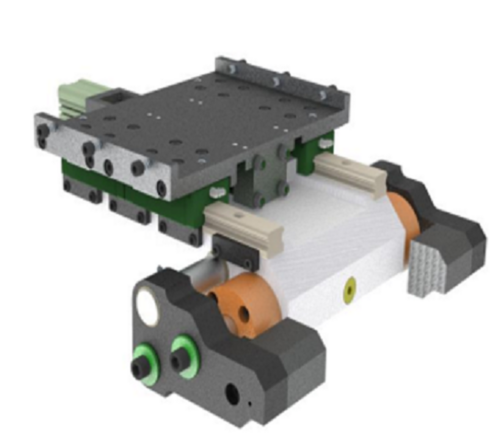

Material Handling Systems - Hydraulic Gripper

100 INR/Number

Product Details:

- Features Adjustable grip force, Easy integration with automation

- Handle Type Ergonomic

- Motor Type Hydraulic motor

- Rotation Type 360-degree rotation

- Equipment Type Material Handling

- Lifting Speed 0.1-0.3 m/s

- Control System Manual and Automatic

- Click to View more

X

Material Handling Systems - Hydraulic Gripper Price And Quantity

- 100 INR/Number

- 1 Number

Material Handling Systems - Hydraulic Gripper Product Specifications

- Robust construction, corrosion-resistant

- Ergonomic

- 2 kW

- Adjustable grip force, Easy integration with automation

- Heavy duty, easy operation, low maintenance

- 360-degree rotation

- Hydraulic motor

- 0.1-0.3 m/s

- Up to 3 meters

- Material Handling

- 220V/380V

- 1000 kg

- Up to 1000 kg

- Hydraulic and Electric

- Manual and Automatic

- New

Material Handling Systems - Hydraulic Gripper Trade Information

- All India

Product Description

We have brought material handling systems hydraulic gripper, which is a device for grasping objects in a range of industrial automation applications. The gripper is incredibly demanded in heavy lifting and manipulation of objects applications. The gripper is further demanded in automotive, aerospace, manufacturing settings. The precise positioning of objects is promoted with material handling systems hydraulic gripper. It holds the metal parts for welding operations for a consistent welding purpose. This essential tool is utilized in industrial automation applications. The gripper is a reliable choice in a range of applications.

Reliable Hydraulic Performance for Diverse Needs

This hydraulic gripper delivers consistent heavy-duty performance, with adjustable lifting speed (0.1-0.3 m/s) and working pressure range of 80-160 bar. Its ergonomic handle and 360-degree rotation capability make it versatile for various material handling tasks, optimizing workflows in industrial settings.

Advanced Safety & Automation

Equipped with robust controls, including manual and automatic mode, the gripper is designed to minimize operational risk while maximizing efficiency. Its CE certification and low noise output help ensure safe and comfortable usage, while easy automation integration supports modern workshops and warehouses.

FAQ's of Material Handling Systems - Hydraulic Gripper:

Q: How does the hydraulic gripper adapt to different material sizes?

A: The jaw opening range of 50 mm to 350 mm allows the hydraulic gripper to easily handle a wide variety of material sizes, making it suitable for diverse industrial applications.Q: What is the recommended working environment for this gripper?

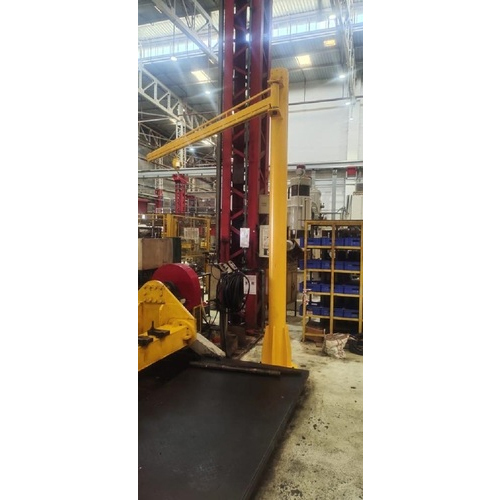

A: The hydraulic gripper operates effectively in ambient temperatures from -10C to 50C, and its powder-coated, corrosion-resistant finish ensures suitability for workshops, factories, and warehouses.Q: Where can this hydraulic gripper be installed?

A: This equipment is compatible with both floor mounting and overhead crane systems, providing flexibility for different layout and workflow requirements in industrial environments.Q: What is the process for operating the gripper?

A: Operation can be manual or automated via remote or hand controls, utilizing a hydraulic motor and an ergonomic handle for user comfort. The control system supports both manual and automatic operation for ease of use.Q: What lifting capacity and height does the gripper support?

A: The hydraulic gripper can lift up to 1000 kg to a maximum height of 3 meters, making it ideal for heavy-duty material handling in large-scale operations.Q: What are the key benefits of using this hydraulic gripper?

A: Key benefits include robust construction, low maintenance requirements, adjustable grip force, corrosion resistance, and seamless integration with automation systems for greater efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email