Material Handling Systems

Product Details:

- Handle Type Ergonomic

- Equipment Type Material Handling Systems

- Motor Type Three Phase Induction Motor

- Belt Type PVC / Rubber

- Rack Capacity Up to 5000 kg/rack

- Rotation Type 360 Swivel

- Forklift Optional Attachment

- Click to View more

X

Material Handling Systems Product Specifications

- Up to 40 meters

- New

- Three Phase Induction Motor

- 5000 kg

- PU Coated / Cast Iron

- Ergonomic

- 500 kg to 5000 kg

- Electric

- PLC Controlled

- Material Handling Systems

- Corrosion-resistant, Heavy-Duty, Sturdy Construction

- 0.5 m/s to 1 m/s

- Low Maintenance, Easy Installation

- 360 Swivel

- 6 meters

- Optional Attachment

- 220 V / 380 V

- Up to 5000 kg/rack

- Modular Design, High Efficiency

- PVC / Rubber

- 2 kW to 7.5 kW

Material Handling Systems Trade Information

- All India

Product Description

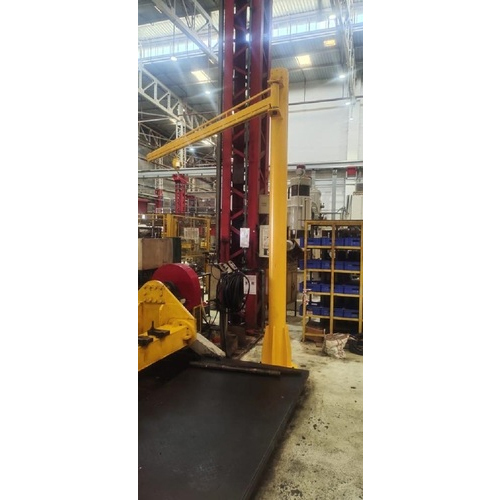

Material Handling Systems we propose are commonly used in production and packaging units of varied industries for making process easier and faster. Designed and manufactured with high precision, the systems take a little effort to get installed due to their heavy weight, robust construction and multiple parts to assemble. Made of the best grade material handling mechanisms, Material Handling Systems are available in varied capacities, dimensions, and designs to meet varied material handling requirements of innumerable respected clients.

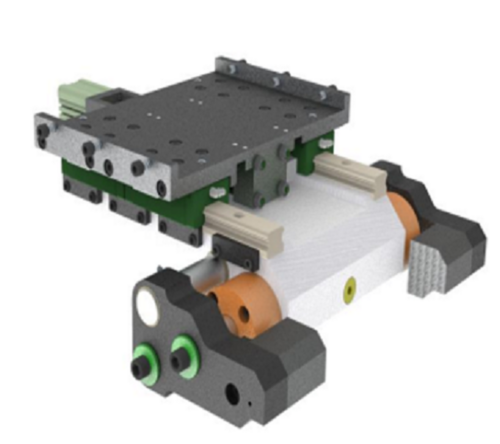

High-Performance Modular Design

Designed for adaptability, these material handling systems feature a modular layout that allows customization in dimensions and operational modes. With a conveyor belt length of up to 40 meters and adjustable belt width, users can configure the system for optimal workflow efficiency in various industrial environments.

Robust Safety and Control Features

Safety is prioritized through integrated overload protection and emergency stop systems. Controlled by advanced PLC units, these systems ensure precise operation and quick response in critical situations, further supporting safe handling of heavy loads up to 5000 kg per lift.

Easy Maintenance & Efficient Service

The frame provides easy access panels, simplifying routine service and reducing system downtime. Engineered for low maintenance with corrosion-resistant components, these systems deliver reliable performance over extended periods, minimizing disruptions in warehouse or factory operations.

FAQ's of Material Handling Systems:

Q: How can the dimensions of the material handling system be customized for specific requirements?

A: The dimensions, including conveyor width (300 mm to 1000 mm) and belt length (up to 40 meters), can be tailored during the design phase to match unique operational needs. Simply share your requirements with our technical team for a bespoke solution.Q: What are the main safety features incorporated in these material handling systems?

A: These systems include overload protection and emergency stop features as standard to enhance workplace safety and protect both operators and equipment during use.Q: When is it advisable to opt for a mobile versus stationary installation?

A: A mobile installation suits facilities needing flexible material transport across various zones, while stationary setups are ideal for fixed locations or production lines where frequent relocation isn't required.Q: Where are these material handling systems commonly used?

A: They are widely utilized in warehouses, production factories, and logistics units to streamline handling and lifting of heavy materials, improving operational efficiency in these environments.Q: What is the process for installing these systems?

A: Installation is straightforward, thanks to their modular design and easy access panels. Our service team assists with setup and provides training, ensuring seamless integration into your facility's workflow.Q: How does the PLC control system enhance operational efficiency?

A: The integrated PLC control system automates and streamlines system operations, enabling precise handling, adjustable speed, and safer processing of loads, which results in increased productivity and reduced manual intervention.Q: What are the benefits of using a three-phase induction motor in these systems?

A: Three-phase induction motors deliver reliable, energy-efficient power, ensuring smooth operation, consistent lifting speeds, and long-term durability, even under heavy-duty use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email